Brian Rosenberger worked for years at an aircraft manufacturing company, which coincidentally was owned by Glenn L. Martin is the company's legacy. On a long drive from his home in Texas to the snow of Colorado in 2010, Rosenberger, along with his son and friends, covered a lot of topics, but the topic Rosenberger kept coming back to was building a snowboard (his favorite The plank of) at that time) like some airplane parts – from a single piece of aluminum.

One friend in particular, Ron Chambers, eventually got tired of all the talking and said he would finance an effort to get things started. In 2013, Rosenberger contacted Leif Sunde, founder of Denver Sports Lab, an Olympic-level ski tuning shop, to begin testing the flex properties of various composite snowboards on the market. By 2014 Rosenberger had some full-aluminum prototypes ready for testing. Obviously, the results on the ice were very encouraging.

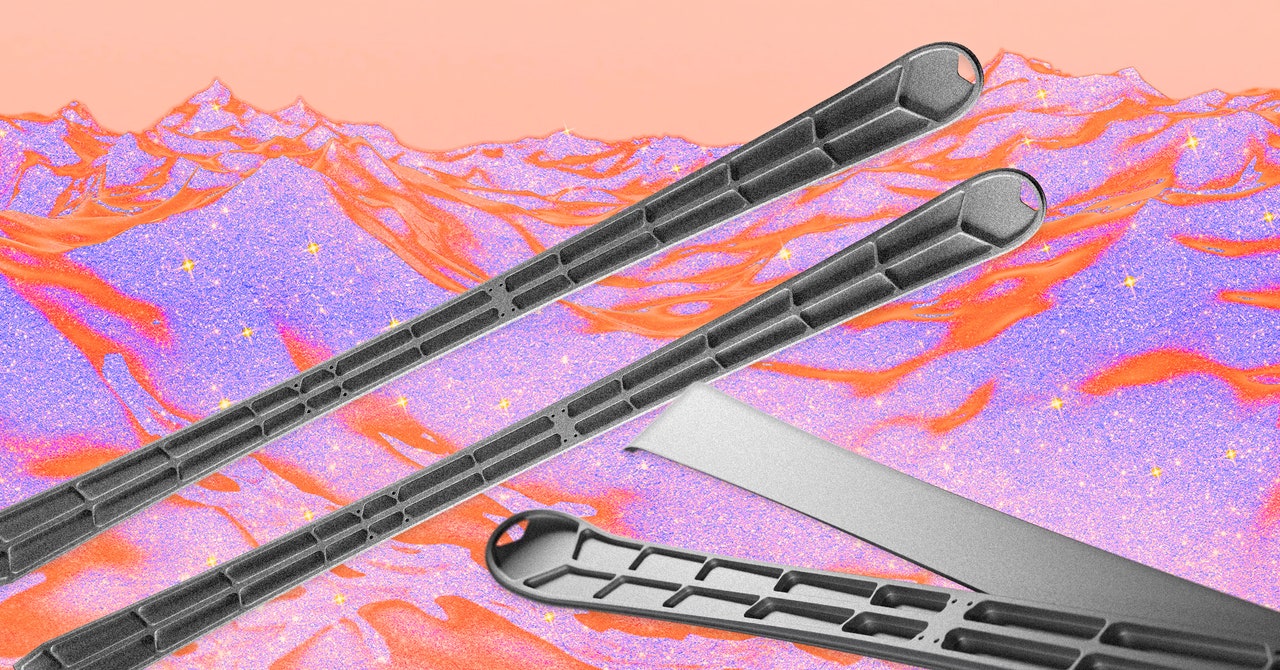

Over the years more prototypes were built, and a switch from snowboards to skis was made. In July 2023, Metal1 Ski Corporation (m1 ski) was formed: Rosenberger was appointed CEO, Chambers as COO, Sana Fatima to lead fundraising and strategy, and Sunde as director of product.

Why aluminium?

The first question that comes to many people's minds is whether the metal attached to a soda can or cooking foil is strong enough to endure the rigors of a mountain – especially along the edges, which are traditionally made of steel. It is made of.

“Aluminum is about an order of magnitude stiffer than the snow a ski will hit,” says Rosenberger. The trade-off for many materials, including metals, is the more difficult they become, the more brittle they become. Aluminum, according to M1, is tough enough to handle ice, but flexible enough that when it encounters rocks, it won't stick or break easily, even in cold winter conditions. Indeed, some ski manufacturers opt for a softer steel edge when making park-oriented skis because harder steel is more likely to chip or break when sliding on tracks at a ski park.

Core shots – when the core of the ski is exposed to moisture and begins to warp or rot – will never happen, because there is no core, and the aluminum base will deflect rocks better than any extruded polyethylene base. And, for this reason, no rock will ever break the banks.